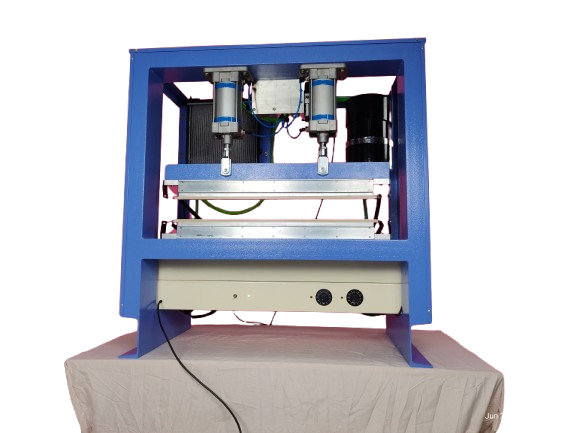

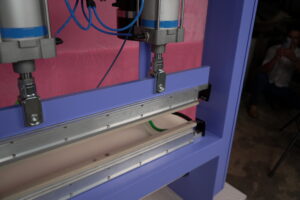

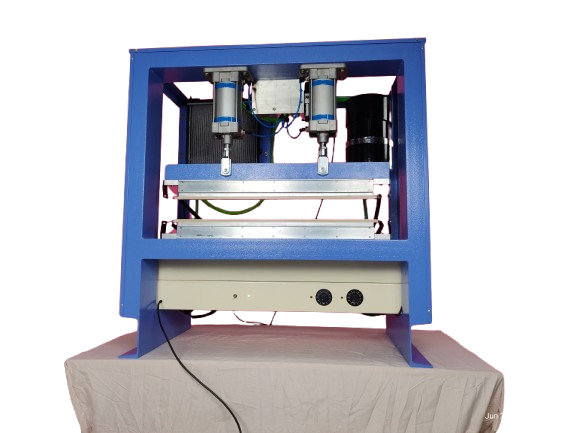

Filter media welding machines are essential in the industrial filter manufacturing units. At times, these machines are used as the substitutes for high frequency welding machines.

Features

Media to Pouches

Filter media is cut, folded, and sealed into pouches using heat.

Joining Pouches

Pouches are layered or stacked to improve filtration efficiency.

Heavy Sealing Machines

Specialized machines ensure airtight seals for industrial filters.

Advantages of Filter Media Welding Sealers

Increased Efficiency

Form sealing machines automate the packaging process, significantly reducing the time required for manual packing. This increases overall production speed and throughput.

Cost-Effective

By automating the packaging process, labor costs are reduced, and material wastage is minimized. These machines also allow for continuous operation, making them a cost-efficient option in the long run.

Consistency and Precision

The machines provide highly consistent and precise sealing, ensuring that every package is uniform in shape and size. This reduces the likelihood of human error and ensures that the seal quality is maintained across large production runs.

Product Protection

The sealed packaging helps protect the product from contamination, moisture, and air, extending the shelf life and preserving the quality of the product. This is particularly important for food, pharmaceuticals, and other sensitive products.

Versatility

Form sealing machines can accommodate a variety of materials and products. Whether it's food, pharmaceutical, or cosmetic items, these machines can handle different shapes, sizes, and materials like plastic, foil, and laminates.

Reduced Material Wastage

With precise cutting and sealing, form sealing machines minimize material wastage compared to manual methods, resulting in a more sustainable production process.

Improved Product Appearance

The packaging produced by form sealing machines is often more polished and professional in appearance, which enhances the product’s visual appeal to customers.

Enhanced Sealing Quality

Form sealing machines ensure strong and durable seals that help to prevent leaks or tampering. The packaging maintains its integrity during transportation and storage.

Increased Production Capacity

These machines can operate continuously, increasing production capacity and reducing the need for downtime. This is especially beneficial for high-volume industries.

Customizable Packaging

Many form sealing machines offer flexibility in customizing packaging formats and sizes, allowing manufacturers to meet specific product needs and market demands.

Hygienic and Safe

These machines typically operate in sanitary environments, with built-in safety features to prevent contamination. For food and medical products, hygiene is essential, and these machines meet those standards.

Energy Efficiency

Modern form sealing machines are designed to be energy-efficient, helping companies reduce operational costs while maintaining high levels of performance.

Who we really are

Created the perfect Form sealing machines

Sealing machines are devices used to securely close packaging materials, such as plastic bags, pouches, or containers, to ensure the safety, freshness, and quality of the contents. These machines are widely used in various industries, including food processing, pharmaceuticals, cosmetics, and electronics.